Tawagan Kami

+86-19858305627

Mag-email sa Amin

sales@maple-machinery.com

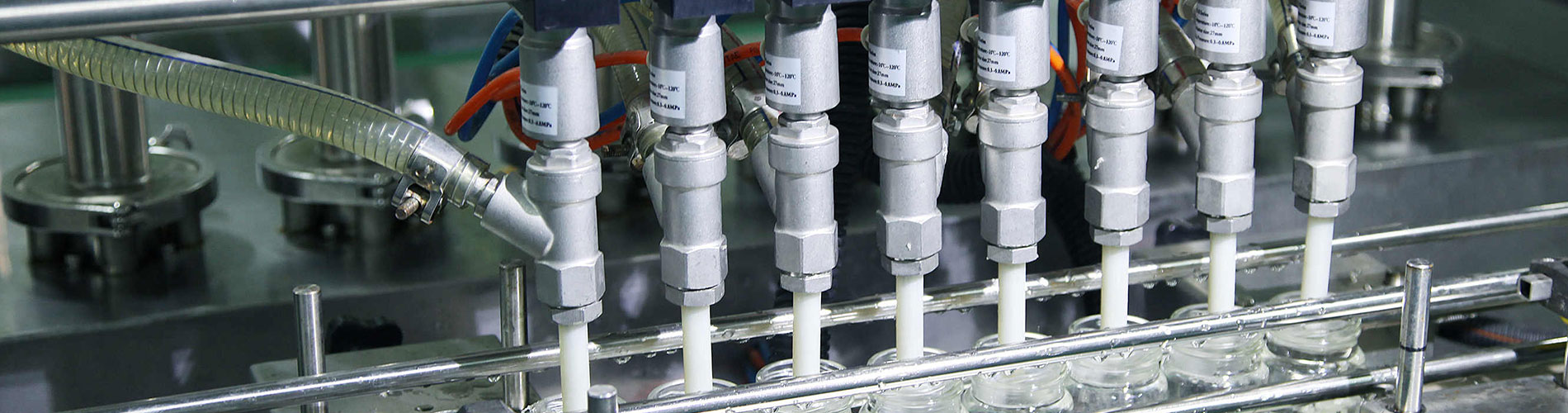

Iron sand casting para sa valve assemblies Mga Manufacturer

Nagbibigay ang aming pabrika ng sand casting, closed die forging, open die forging, atbp. Ang matinding disenyo, kalidad ng mga hilaw na materyales, mataas na pagganap at mapagkumpitensyang presyo ang gusto ng bawat customer, at iyon din ang maiaalok namin sa iyo. Kumuha kami ng mataas na kalidad, makatwirang presyo at perpektong serbisyo.

Mainit na Produkto

Mga Bahagi ng Pagpapanday ng Hindi kinakalawang na Asero sa Industriya ng Highway

Nag-aalok ang Maple machinery sa mga customer ng malawak na hanay ng Off Highway Industry Stainless Steel Forging Parts. Ang aming pangunahing kakayahan ay ang pagbuo ng mga solusyon sa system na partikular sa customer para sa Off Highway Industry upang matugunan ang mga pinaka-hinihingi na kinakailangan. Bilang karagdagan sa dami, katumpakan, kaligtasan at pagiging maaasahan, ang aming mga customer ay lalong naghahanap ng higit na mahusay na teknolohiya at kahusayan sa ekonomiya.Recycling Industry Steel Forging Parts

Ang makinarya ng Maple ay nagbibigay sa aming mga customer ng mataas na kalidad na Recycling Industry Steel Forging Parts, tinitiyak ang kanilang pagmamay-ari ng mga bahagi ng perpektong kalidad, tinitiyak ang maximum na repeatability at pinakamainam na produktibidad/competitiveness at preventive maintenance ng mga kagamitan sa transportasyon, Regular na mga pagsusuri sa kaligtasan at, kung naaangkop, ang mga refurbishment at pagpapahusay ay isinasagawa upang magbigay ng mas mahusay at maaasahang base para sa pag-install ng makina..Recycling Industry Steel Sand Casting Parts

Itinayo ng Maple machinery ang reputasyon nito sa Recycling Industry Steel Sand Casting Parts na ibinibigay namin sa mga kumpanya sa buong mundo. Sa ngayon, pinapanatili ng Maple machinery ang pilosopiyang ito sa pamamagitan ng pagbibigay ng mga de-kalidad na produkto na nakakatugon sa mga pangangailangan sa pag-cast at pagma-machine ng mga customer sa buong mundo. Nakamit ito sa pamamagitan ng pagbibigay ng mga naka-target na teknikal at komersyal na alok na may layuning i-optimize ang mga gastos at magbigay ng mga makabagong teknikal na solusyon. Gumagawa ang makinarya ng maple ng lumalawak na hanay ng mga de-kalidad na Steel Sand Casting Parts. Pagkatapos ng centrifugally casting bronze parts para matugunan ang pinaka-hinihingi na mga customer..Recycling Industry Mga Bahagi ng Stainless Steel Casting

Ginagamit ng Maple machinery ang pinakabagong teknolohiya sa aming proseso ng Investment Casting para makagawa ng de-kalidad na Recycling Industry Stainless Steel Casting Parts nang epektibo at nasa oras. Patuloy kaming naghahanap ng mga bagong teknolohiya at mga makabagong paraan upang mapabuti ang aming proseso ng paglalagay ng pamumuhunan sa Recycling Industry, ang aming kahusayan, aming kalidad, at paikliin ang aming lead time.Civil Engineering Stainless Steel Forging Parts

Ang kahalagahan ng stainless steel type beams sa malawak na mundo ng construction, engineering, construction at structural steel. Ang mga forged stainless steel beam ay naging mahalagang bahagi ng Civil Engineering sa loob ng mahigit 15 taon. Bilang supplier ng Stainless Steel Parts, gumagawa ang Maple machinery ng iba't ibang Civil Engineering Stainless Steel Forging Parts na iniayon para sa iyo ng aming team. Kami ay isang pinagkakatiwalaang tagagawa ng iyong mga bahagiOil at Gas Industry Stainless Steel Forging Parts

Maple machinery ay matatagpuan sa Ningbo, China para sa mga bahagi ng produksyon, warehousing at sub-transportasyon ng Oil & Gas Industry Stainless Steel Forging Parts, at maayos ang posisyon nito upang matugunan ang mga pangangailangan ng mga pangunahing supplier sa industriya ng langis at gas. Kasama ng mga certified at aprubadong supplier mula sa aming mga customer sa maraming bansa, mayroon kang pagkakataon na samantalahin ang mga benepisyo ng low cost country sourcing at alam na salamat sa mga produkto ng Maple ay mayroong 100% kalidad na garantiya

Magpadala ng Inquiry

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy