Tawagan Kami

+86-19858305627

Mag-email sa Amin

sales@maple-machinery.com

Bahay

>

Mga produkto

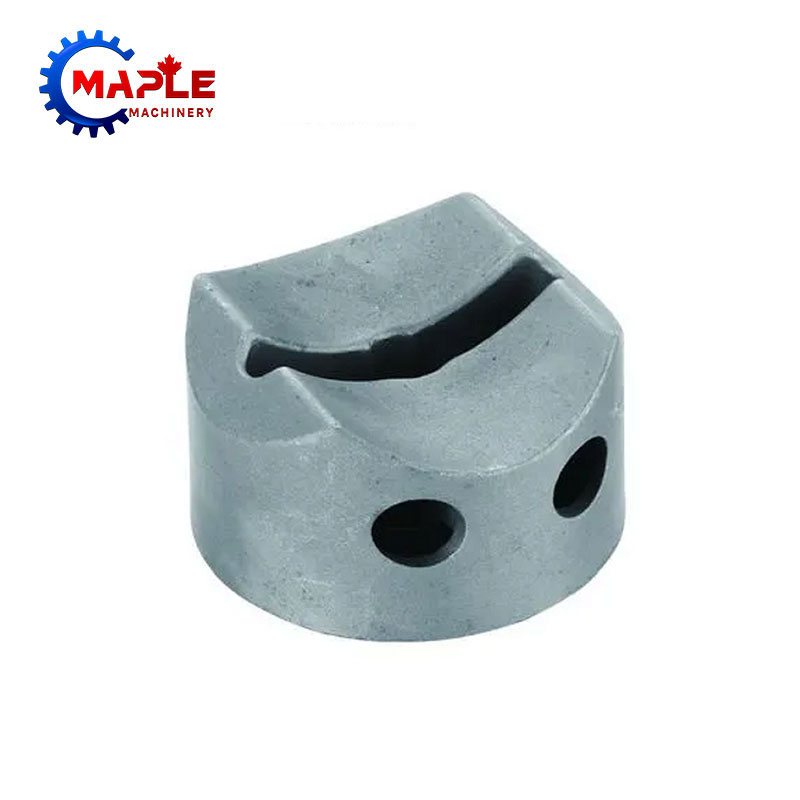

> Mga Bahagi ng Paghahagis ng Hindi kinakalawang na Bakal na Industriya sa Labas ng Highway

Mga Bahagi ng Paghahagis ng Hindi kinakalawang na Bakal na Industriya sa Labas ng Highway Mga Manufacturer

Nagbibigay ang aming pabrika ng sand casting, closed die forging, open die forging, atbp. Ang matinding disenyo, kalidad ng mga hilaw na materyales, mataas na pagganap at mapagkumpitensyang presyo ang gusto ng bawat customer, at iyon din ang maiaalok namin sa iyo. Kumuha kami ng mataas na kalidad, makatwirang presyo at perpektong serbisyo.

Mainit na Produkto

Food Process Machine Mga Bahagi ng Ductile Iron Casting

Mula nang magsimula ito, nakatuon kami sa lugar ng kapasidad ng pagiging produktibo, upang matugunan ang lumalaking pangangailangan sa merkado, patuloy naming pinapabuti ang aming Mga Bahagi at kalidad ng Food Process Machine na Ductile Iron Casting Parts. Produksyon ng lahat ng mga produkto mula sa mga bahagi ng makina hanggang sa mga medium na bahagi upang mapabuti ang kanilang sariling mga kakayahan. Matugunan ang mga pangangailangan ng customer.Mga Bahagi ng Valve Steel Investment Casting

Sa maple machinery, mayroon kaming malawak na karanasan sa Casting para sa Valve Steel Investment Casting Parts, na nagbibigay-daan sa aming mga customer na makakuha ng mataas na kalidad na mga casting mula sa proseso ng investment casting sa isang matipid na halaga. Mayroon kaming mahusay na teknikal na koponan na may maraming taon ng karanasan upang mabigyan ka ng pinakamahusay na disenyo ng paghahagis ng pamumuhunan. Anumang tulong na kailangan - mula sa mga simpleng pagsusuri sa pagpaparaya hanggang sa ganap na kasabay na engineering - ay makukuha sa aming foundry site. Ang Valve Steel Investment Casting Parts, maple machinery ay makakapagbigay sa iyo ng pinakamahusay.Food Process Machine Mga Bahagi ng Iron Sand Casting

Mataas na kalidad ng cast, machined parts sa mapagkumpitensyang presyo mula sa maaasahang mga supplier. Ang Maple Machinery ay isang sikat na tagagawa ng mga bahagi ng metal sa China at isang maaasahang supplier ng Food Process Machine. Ang Food Process Machine ay nangangailangan ng mataas na katumpakan ng Food Processing Machine Mga Bahagi ng Iron Sand Casting. Nagagawa namin ang isang mahusay na trabaho ng mga pangunahing supplier ng produkto ng lahat ng mahahalagang bahagi ng system.Mga Bahagi ng Heavy Industry Ductile Iron Casting

Matatagpuan sa Ningbo, China, malapit sa daungan ay may sariling planta ng produksyon, pati na rin ang isang pangkat ng engineering na nakatuon sa pagbibigay sa mga customer ng mga solusyon upang gumana nang may kalidad at pinakabagong teknolohiya. Nagsisilbi ito sa buong mundo. Salamat sa aming kadalubhasaan, ang aming makabagong makinarya at mataas na kalidad na teknolohiya ng produksyon ang yugto ng produksyon ay naghahatid ng tamang dami ng mataas na kalidad na Heavy Industry Ductile Iron Casting Parts..Mga Cast Iron Hydraulic Manifold

Naninindigan ang Maple Machinery bilang isang pinagkakatiwalaang internasyonal na kaalyado sa larangan ng Cast Iron Hydraulic Manifold. Ang aming mga alok ay nakakahanap ng malawak na aplikasyon sa iba't ibang industriya tulad ng automotive, kemikal, konstruksiyon, at pagmimina. Ang pinagkaiba sa amin ay ang aming pangkalahatang diskarte sa serbisyo. Hindi lamang kami nagdadalubhasa sa paggawa ng casting ngunit mahusay din kami sa machining at heat treatment, na makabuluhang pinapa-streamline ang proseso ng pagtupad ng order at tinitiyak ang mabilis na paghahatid. Binibigyang-diin ng komprehensibong modelo ng serbisyong ito ang aming pangako sa kahusayan at kasiyahan ng kliyente.Hydraulic System Mga Bahagi ng Iron Sand Casting

Gumagawa ang Maple Leaf Machinery Co., Ltd. ng Hydraulic System Iron Sand Casting Parts, at ginagawa naming perpekto ang aming talento sa nakalipas na 15 taon. Ginagamit namin ang aming kaalaman upang maipasa ang pinakamahusay na mga kasanayan at pamamaraan ng Hydraulic System Iron Sand Casting Parts, at gamitin ang mga pinakabagong pag-unlad sa mga proseso ng paghahagis. Pangunahing nakatuon ang kumpanya sa sand mold casting, shell mold casting at lost wax casting, at patuloy na nagpapalawak ng mga sumusuportang pasilidad, teknolohiya, kagamitan at serbisyo.

Magpadala ng Inquiry

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy