Tawagan Kami

+86-19858305627

Mag-email sa Amin

sales@maple-machinery.com

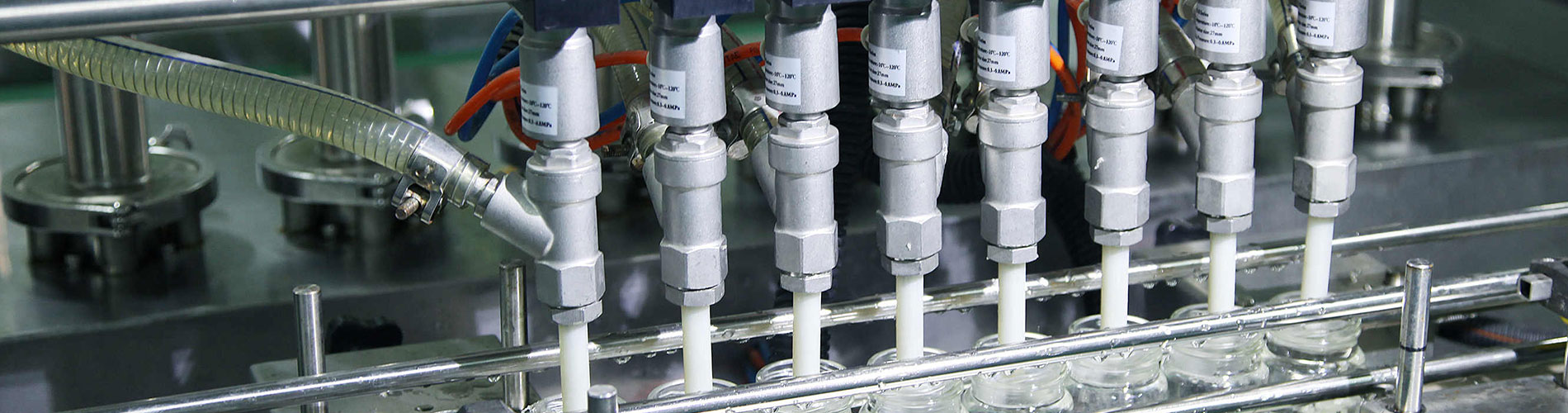

Food Process Machine Steel Investment Casting Parts Mga Manufacturer

Nagbibigay ang aming pabrika ng sand casting, closed die forging, open die forging, atbp. Ang matinding disenyo, kalidad ng mga hilaw na materyales, mataas na pagganap at mapagkumpitensyang presyo ang gusto ng bawat customer, at iyon din ang maiaalok namin sa iyo. Kumuha kami ng mataas na kalidad, makatwirang presyo at perpektong serbisyo.

Mainit na Produkto

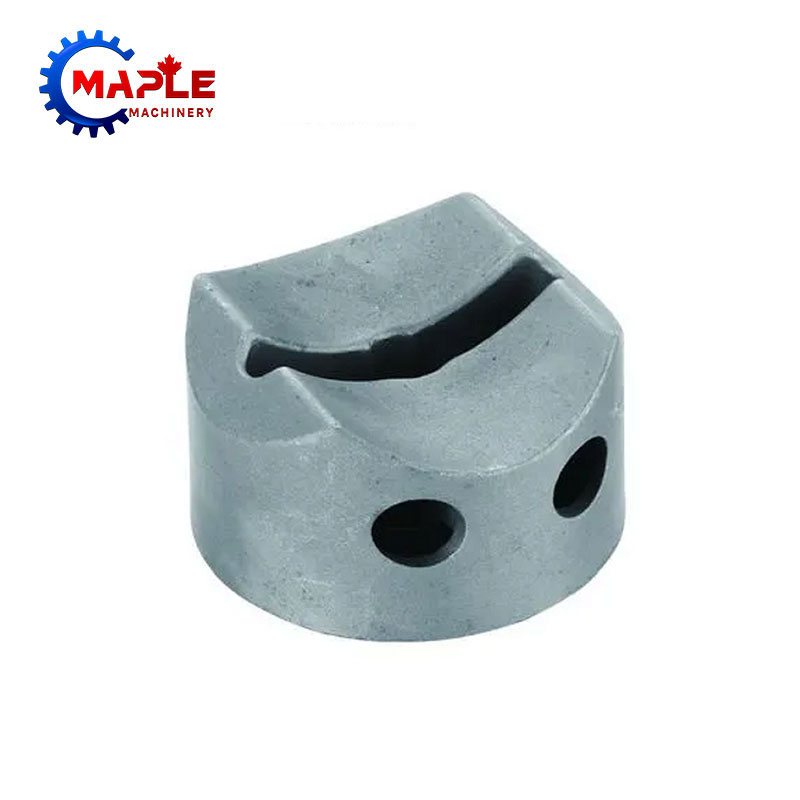

Makinaryang Pang-agrikultura Steel Lost Wax Casting Parts

Ang maple machinery ay isang kilalang supplier. Bilang karagdagan sa kanilang tungkulin bilang mga komersyal na vendor, ang relatibong mataas na mga layunin sa pagganap na kinakailangan ng mga application na ito ay nangangailangan ng katumbas na mas mahigpit na mga pagtutukoy. Ang Agricultural Machinery Steel Lost Wax Casting Parts ay isa sa aming pinakamahusay na mga produkto. Ang malaking bilang ng mga pag-export bawat taon ay isang patunay ng ating lakas.Makinarya sa Konstruksyon Mga Bahagi ng Ductile Iron Casting

Ang kumpanya ay may higit sa sampung taong karanasan sa Construction Machinery Ductile Iron Casting Parts. Sa pamamagitan ng paggamit ng mga computer at mga automated na linya ng produksyon, nagagawa naming makuha ang pinakamahusay na paraan ng casting na ito, paglikha ng mga kumplikadong hugis, paggawa ng mga press lines, pag-aalis ng mga parting lines, at paggawa ng mga casting na may napakataas na dimensional tolerance.Civil Engineering Mga Bahagi ng Iron Sand Casting

Mula nang mabuo ang kumpanya, ang Maple machinery na Iron Sand Casting Parts ay dalubhasa sa paggawa ng mataas na kalidad at kumplikadong mga iron casting para sa maraming industriya mula sa unang araw. Nagbibigay kami sa aming mga customer ng kumpletong solusyon para sa mga bahagi ng aluminyo. Sa aming organisasyon, ginagawa namin ang bawat sub-process na nauugnay sa paggawa ng mga kumplikadong casting. Ginagarantiyahan nito ang isang kumpletong in-house na solusyon sa Civil Engineering Iron Sand Casting Parts kung saan nakikinabang ang mga customer sa superyor na kalidad at pagiging maaasahan na karapatan nilang asahan mula sa kanilang mga supplier ng Iron Sand Casting Parts..Civil Engineering Stainless Steel Casting Parts

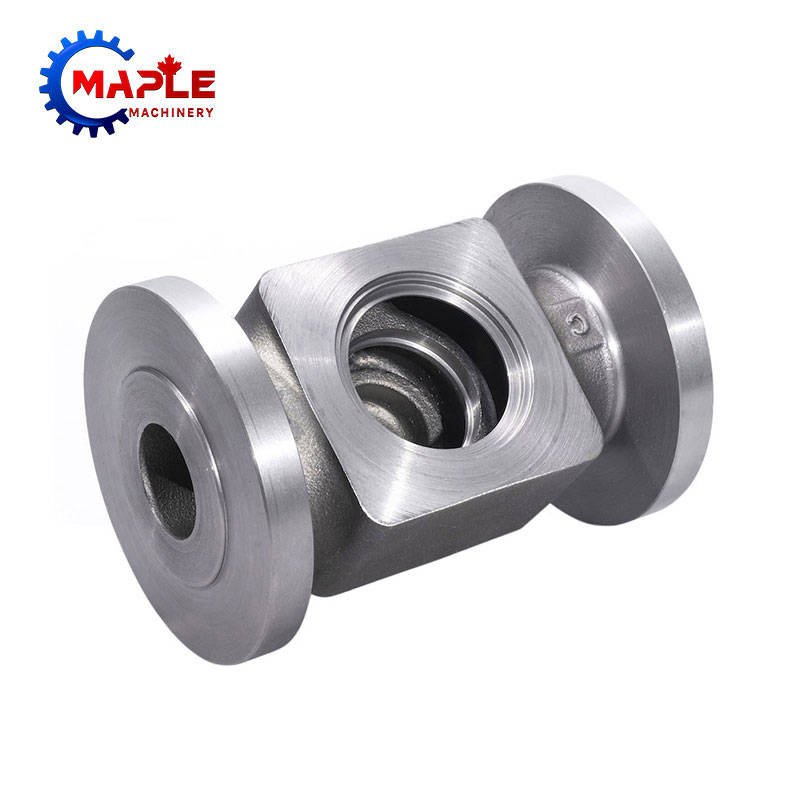

Ang Maple machinery ay isang supplier ng Civil Engineering Stainless Steel Casting Parts na gumagawa ng mga kumplikadong casting na may napakataas na katumpakan gamit ang "nawalang wax" na paraan. Dahil sa pangkalahatang pamamaraang ito, ang aming mga inhinyero ay may malaking kalayaan sa disenyo ng produkto at pagpili ng materyal. Nangangahulugan ito na, sa pagkonsulta sa iyo, makakagawa kami ng pinakamahusay na paghahagis na nakakatugon sa iyong eksaktong mga hangarin at kinakailangan. Ang Maple machinery ay ang iyong development partner para sa matagumpay na casting na may layuning makagawa ng pinakamahusay na produkto ng casting sa pamamagitan ng mutual consultation.Food Process Machine Mga Bahagi ng Stainless Steel Casting

Para sa Food Process Machine, kumikilos ang mga Maple machinery engineer bilang extension ng iyong organisasyon sa pagbuo ng precision casting. Sa pamamagitan ng palaging pagsasaalang-alang kung ang mga bagay ay maaaring "mas mahusay sa teknikal, naiiba, mas mura at/o mas simple", nakukuha namin ang pinakamahusay na solusyon sa isang mapagkumpitensyang presyo. Ikinalulugod naming ibahagi sa iyo ang aming kaalaman sa mga diskarte sa Casting para magdisenyo ng pinakamahusay na Food Process Machine Stainless Steel Casting Parts.Recycling Industry Steel Lost Wax Casting Parts

May komprehensibong portfolio ng mga produkto at serbisyo ang Maple machinery. Bilang resulta, ang mga custom na tool ng Recycling Industry Steel Lost Wax Casting Parts na idinisenyo at mataas na pagganap ng mga produkto ay ginagamit upang lumikha ng mga solusyon sa pagpoproseso na pinakamahusay na nakakatugon sa pagiging maaasahan ng proseso, katumpakan at mga kinakailangan sa pagiging epektibo sa gastos.

Magpadala ng Inquiry

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy