Tawagan Kami

+86-19858305627

Mag-email sa Amin

sales@maple-machinery.com

Balbula iron sand-formed parts Mga Manufacturer

Nagbibigay ang aming pabrika ng sand casting, closed die forging, open die forging, atbp. Ang matinding disenyo, kalidad ng mga hilaw na materyales, mataas na pagganap at mapagkumpitensyang presyo ang gusto ng bawat customer, at iyon din ang maiaalok namin sa iyo. Kumuha kami ng mataas na kalidad, makatwirang presyo at perpektong serbisyo.

Mainit na Produkto

Recycling Industry Steel Closed Die Forging Parts

Anuman ang hugis ng iyong Recycling Industry Steel Closed Die Forging Parts, kung kailangan ng mga bahaging metal, ang Forecast Industrial Sales ay maaaring ipasadya para sa iyo sa Maple machinery. Ilan lang ito sa mga industriya kung saan gumagawa kami ng mga espesyal na forging at casting: aerospace Automotive construction at Heavy equipment manufacturing at Metalworking Forestry Mining Oil & Gas.Civil Engineering Steel Sand Casting Parts

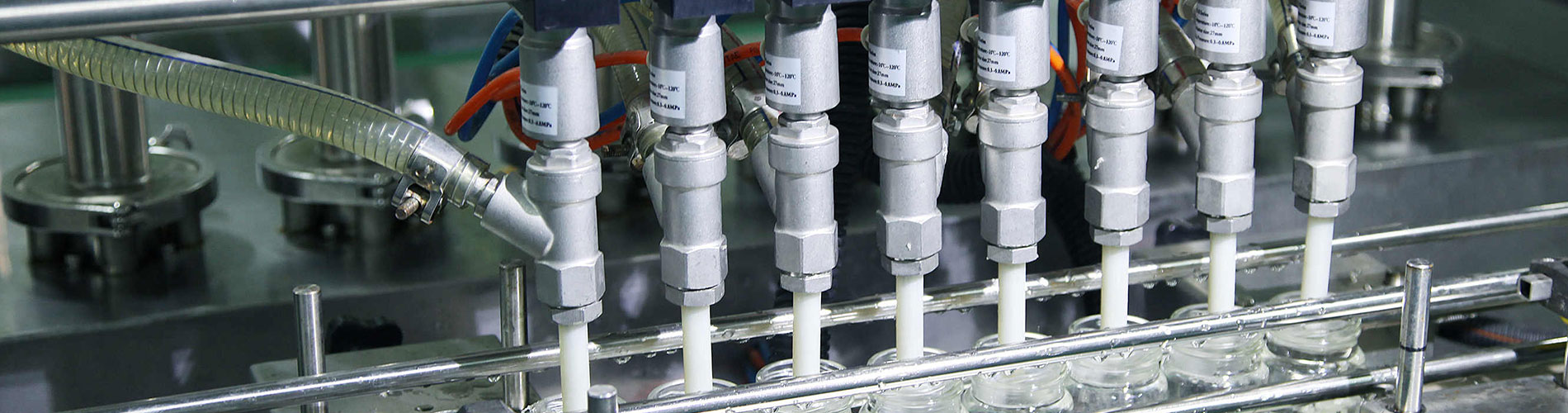

Ang Maple machinery ay isang kumpanyang nag-specialize sa paggawa ng maliliit at katamtamang cast iron at steel castings. Ang tindahan ay gumagawa ng iba't ibang mga produkto para sa Civil Engineering Steel Sand Casting Parts. Ang lahat ng mga produkto ay kontrol sa laboratoryo, at nagbigay ng sertipiko ng kalidad ng produkto.Mga Bahagi ng Valve Steel Forging

We at Maple machinery guarantee the quality and impeccable service of every Valve Steel Forging parts. We strive for excellence every day, using all of our expertise and tremendous commitment to ensure maximum efficiency. We aim at innovation to create a better future and bravely face every new challenge. Product Introduction The different Forging techniques offered by Maple machiney Forging solutions enable us to forge the different Valve Steel Forging parts of valves all of which are designed to the customer's requirements and are also checked and verified in a simulator before forging. The resources and skills of our staff enable us to forge any type of material that is processed on our heat treatment equipment and completed after conducting final destructive and non-destructive tests. They are provided on delivery terms agreed with the customer and include all required documents and certificates. 2. Product Parameter (Specification) Item Valve Steel Forging parts Roughness Ra 1.6 Tolerance ±0.01mm Material Alloy Steel Certification ISO 9001:2015 Weight 0.01-60KG Machining CNC Heat Treatment Quenching & Tempering Inspection MT/UT/X-Ray Lead Time 30 Days Package Plywood Case Method Closed Die Forging Capacity 50000 Pcs / Month Origin Ningbo, China 3. Maple’s Services for Valve Our Valve Steel Forging parts have a worldwide reputation for their high quality and reliability. With our state-of-the-art testing laboratories and highly qualified workforce, we combine the highest standards of technology, quality and productivity. Accurate delivery time, fast service, we get the customer's praise. 4.Supporting Service for Valve parts As mentioned above, in order to work in adverse conditions, the performance of the Valve Valve Steel Forging parts must be excellent. Therefore, it’s not enough to only produce raw castings or forgings, but also need heat treatment, machining, surface treatment, NDT testing, etc. Heat treatment: heat treatment is the critical step to improve the mechanical properties of the workpiece. We can formulate the process according to the strength requirements of the parts, and improve the mechanical properties of the parts such as hardness, yield strength, tensile strength and elongation by heat treatment Machining: we have our own machine shop, and can complete almost all machining requirements with advanced equipment. Surface treatment: the purpose of surface treatment is to make parts work in adverse environment. Zinc plating can prevent parts from rusting; Nickel plating can enhance the wear resistance and corrosion resistance of parts; Phosphating can prevent parts from corrosion… Non-destructive testing (NDT): NDT is the last and most important step. Maple will NDT the parts to ensure that there are no surface defects (such as cracks, sand holes, blow holes) and no internal defects (shrinkage and slag) on the delivered parts. Common Material for Agricultural Machinery We have the ability to manufacture all steel standard materials as well as special materials. The following are our common materials for manufacturing Valve Steel Forging parts: Carbon Steel:1015, 1020, 1035, 1045, 20Mn, 25Mn, A570.GrA, SJ355, C45… Alloy Steel:4130, 4135, 4140, 4340, 8620, 8640, 20CrMo, 42CrMo4, 34CrNiMo6, 25CrMo… Stainless steel:304, 304L, 316, 316L, 410, 416, CF8, CF8M, PH17-4, CK20… Gray Iron:GG-15, GG-20, GG-25, Class 20B, Class 25B, Class 30B, GJL-250, GJL-300… Ductile Iron:GGG-40, GGG-50, 60-40-18, 65-45-12, 70-50-05, 80-55-06 QT500-7, QT400-18, QT700-2 … High Chromium cast iron:15%Cr-Mo-HC, 20%Cr-Mo-LC, 25%Cr… Aluminum:AlSi7Mg, AlSi12, AlSi10Mg, A356, A360… High Manganese steel: X120Mn12, Mn12, Mn13… 5.The Parts We Supplying for the Valve We have manufactured a wide range of Valve Steel Forging parts. The following are typical products: Valve joint, Ball valve body, Gate valve body, Choke valve body,Beer valve body,Purification water brass,Hybrid valve, .... 6. Why Closed Die Forging Compared with casting, forging has its special advantages: 1. In the case of the same material, the mechanical properties of forgings are better than those of castings. 2. The forgings strength is higher and the fatigue resistance is stronger. 3. The forgings has better compactness. 4. There are no internal defects and surface defects. 5. Fast production speed, high efficiency, suitable for mass production of products. 6. The product quality is stable.Mga Bahagi ng Heavy Industry Steel Sand Casting

Dalubhasa ang Maple machinery sa mataas na kalidad na Heavy Industry Steel Sand Casting Parts at nagbibigay ng mataas na kalidad na volume production order at single item production. Ang pangunahing materyal ng pandayan ay iba't ibang grado ng bakal. Ang mataas na kalidad na mga hulma sa paghahanda ng paghahagis ay nagbibigay-daan para sa kasunod na pagproseso na may kaunting margin. Ang cast steel ay nagbibigay ng mga produkto na may kumplikadong geometry at samakatuwid ay kadalasan ang tanging paraan upang makagawa ng mga produktong metal na may kumplikadong istraktura.Makinarya sa Agrikultura Mga Bahagi ng Ductile Iron Casting

Supplier ng mga produktong Ductile Iron sa loob ng higit sa 15 taon Ang Maple machinery ay isang propesyonal na tagagawa ng Agricultural Machinery Ductile Iron Casting Parts, para din sa pagmimina, quarrying, Ang power generation at general engineering na industriya ay gumagawa ng malawak na hanay ng mataas na wear-resistant na mga haluang metal at bakal at steel iron castings. ISO 90001 na kalidad na certified na tagagawa, na nagbibigay ng pinakamataas na kalidad ng mga casting sa mga tagagawa ng agrikultura sa mundo at nangungunang mga supplier ng kagamitan sa agrikultura sa mundo.Recycling Industry Mga Bahagi ng Stainless Steel Casting

Ginagamit ng Maple machinery ang pinakabagong teknolohiya sa aming proseso ng Investment Casting para makagawa ng de-kalidad na Recycling Industry Stainless Steel Casting Parts nang epektibo at nasa oras. Patuloy kaming naghahanap ng mga bagong teknolohiya at mga makabagong paraan upang mapabuti ang aming proseso ng paglalagay ng pamumuhunan sa Recycling Industry, ang aming kahusayan, aming kalidad, at paikliin ang aming lead time.

Magpadala ng Inquiry

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy