Tawagan Kami

+86-19858305627

Mag-email sa Amin

sales@maple-machinery.com

Paghahagis ng mga Bahagi ng Pagproseso ng Pagkain Mga Manufacturer

Nagbibigay ang aming pabrika ng sand casting, closed die forging, open die forging, atbp. Ang matinding disenyo, kalidad ng mga hilaw na materyales, mataas na pagganap at mapagkumpitensyang presyo ang gusto ng bawat customer, at iyon din ang maiaalok namin sa iyo. Kumuha kami ng mataas na kalidad, makatwirang presyo at perpektong serbisyo.

Mainit na Produkto

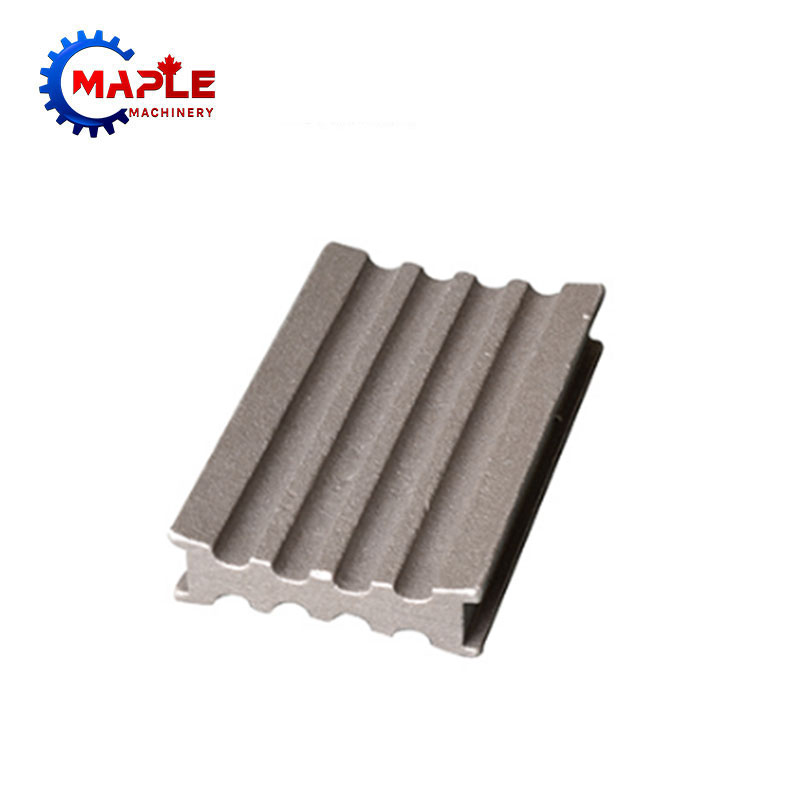

Construction Machinery Steel Forging Parts

Ang closed die forging ay ang pangalawang pinakamalaking saklaw ng negosyo ng Maple machinery at ginagawang eksperto ang aming kumpanya sa mga solusyon sa pagmamanupaktura ng metal. Nakatuon kaming magbigay sa mga customer ng buong hanay ng mga propesyonal na serbisyo sa pagmamanupaktura, at ang pinakamahigpit na kontrol sa kalidad. Kahit anong Construction Machinery Steel Forging Partscomes mula sa aming forger na iba pang mga manufacturer, tatapusin namin ang machining at quality inspection sa sarili naming machine shop para matiyak na 100% perfect ang mga parts na inihatid sa mga customer. Hindi lang namin tinutulungan ang mga customer na bumili ng raw Construction Machinery Steel Forging. Mga bahagi, ngunit tapusin din ang machining at paggamot sa aming sariling machine shop; maaari rin naming pagbutihin ang disenyo ng mga bahagi ng pag-cast o welding sa mga forging na bahagi, at tulungan ang mga customer na magbigay ng mga solusyon sa proseso upang makakuha ng mga forging na may mas malakas na mekanikal na katangian at mas matatag na kalidad.Industriya ng Pagmimina Stainless Steel Casting Parts

Ang MapleMachinery ay nakaranas sa Mining Industry Stainless Steel Casting Parts. Gamit ang malakas na kakayahang mag-cast ng iba't ibang stainless steel, nagbibigay kami ng mga customized na stainless steel na mga bahagi ng casting at mga bahagi para sa industriya ng pagmimina. Makatitiyak kami sa iyo ng mataas na kalidad na Mga Bahagi ng Paghahagis ng Stainless Steel sa Industriya ng Pagmimina. Nakikipagtulungan kami sa aming mga customer upang matiyak na ang mga stainless steel casting na mga produkto / bahagi ay makakagawa ng mga kinakailangang katangian sa pinaka-epektibong paraan. Nagsusumikap kaming maging ang pinakamahusay na stainless steel casting supply chain partner para sa aming mga customer.Food Process Machine Mga Bahagi ng Iron Sand Casting

Mataas na kalidad ng cast, machined parts sa mapagkumpitensyang presyo mula sa maaasahang mga supplier. Ang Maple Machinery ay isang sikat na tagagawa ng mga bahagi ng metal sa China at isang maaasahang supplier ng Food Process Machine. Ang Food Process Machine ay nangangailangan ng mataas na katumpakan ng Food Processing Machine Mga Bahagi ng Iron Sand Casting. Nagagawa namin ang isang mahusay na trabaho ng mga pangunahing supplier ng produkto ng lahat ng mahahalagang bahagi ng system.Food Process Machine Steel Precision Casting Parts

Kami ang nangungunang tagagawa at supplier sa larangan ng Food Process Machine Steel Precision Casting Parts. Ang aming hanay ng produkto ay sinuri ang kalidad laban sa iba't ibang pamantayan ng industriya. Mayroon kaming mahigit 15 taong karanasan sa pag-customize ng mga bahagi para sa industriya ng pagpoproseso ng pagkain. Nag-stock kami ng malawak na hanay ng mga driveshaft, drivetrains, transmission at mga bahagi. Nagtalaga kami ng ilang mahuhusay na propesyonal. Sinusubukan ng aming mga eksperto na maunawaan ang mga kinakailangan ng customer.Industriya ng Pagmimina Gray Iron Casting Parts

Ang Maple machinery ay isang tagagawa ng Mining Industry Gray Iron Casting Parts para sa Industriya ng Pagmimina. Nagbibigay kami ng mga produkto, espesyal na produktong metalurhiko at kagamitan sa produksyon, at nagbibigay ng kinakailangang suporta sa pagkonsulta. Sa mahigit 15 taong karanasan sa mga industriyang ito, makakatulong kami sa paghahanap ng pinakamahusay na teknolohiya at kagamitan para sa Gray Iron casting at mga proseso ng surface treatment.Civil Engineering Steel Casting Parts

Ang Maple machinery ay may higit sa 15 taong karanasan sa industriya ng Steel, kaya marami rin kaming karanasan sa paggawa ng Civil Engineering Steel Casting Parts at mayroon kaming sariling natatanging mga insight. Alam namin kung ano ang pinakamahalaga sa iyo: bukod sa kalidad, garantiya sa paghahatid at presyo, ang solusyon ang mauna. Ang kaalaman sa istruktura, pagpili ng aplikasyon, kaalaman sa materyal na teknolohiya at pagpili ng teknolohiya sa produksyon ay binibigyang halaga.

Magpadala ng Inquiry

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy