Paghahagis ng Bakal

Bilang propesyonal na tagagawa ng paghahagis ng bakal, ang aming espesyal na pamamaraan ay malawakang inilalapat upang maging mas mabigat, mas malakas, at kumplikadong mga hugis para sapaghahagis ng bakal. Kapag nakipag-trade ka sa amin, makakakuha ka ng ilang benepisyo gaya ng mas mababang gastos, mas murang proseso ng paghubog para sa mga kumplikadong disenyo, at mas mataas na katumpakan. Ang isa pang mapagkumpitensyang benepisyo na tinatamasa ng Maple Machinery ay ang nangungunang posisyon nito sa China para sa teknolohiya ng paghahagis. Magbibigay kami ng mga precision casting at micron-level processing services.

- View as

Marine Steel Lost Wax Casting Parts

Ang imprastraktura ng Maple machinery ay higit pang nahahati sa mga sub-division, tulad ng pagmamanupaktura, Quality testing, Sales at Marketing, atbp., upang matiyak ang maayos na proseso ng negosyo. Ang aming mga yunit ng produksyon ay nilagyan ng pinakabagong kagamitan at modernong teknolohiya upang maisagawa ang isang maayos na proseso ng produksyon. Ang mga dalubhasa at may karanasan na staff sa aming team ay pamilyar sa mga kagamitan at makinarya na naka-install, na nagbibigay-daan sa amin upang makagawa ng pinakamagandang kalidad ng Marine Steel Lost Wax Casting Parts.

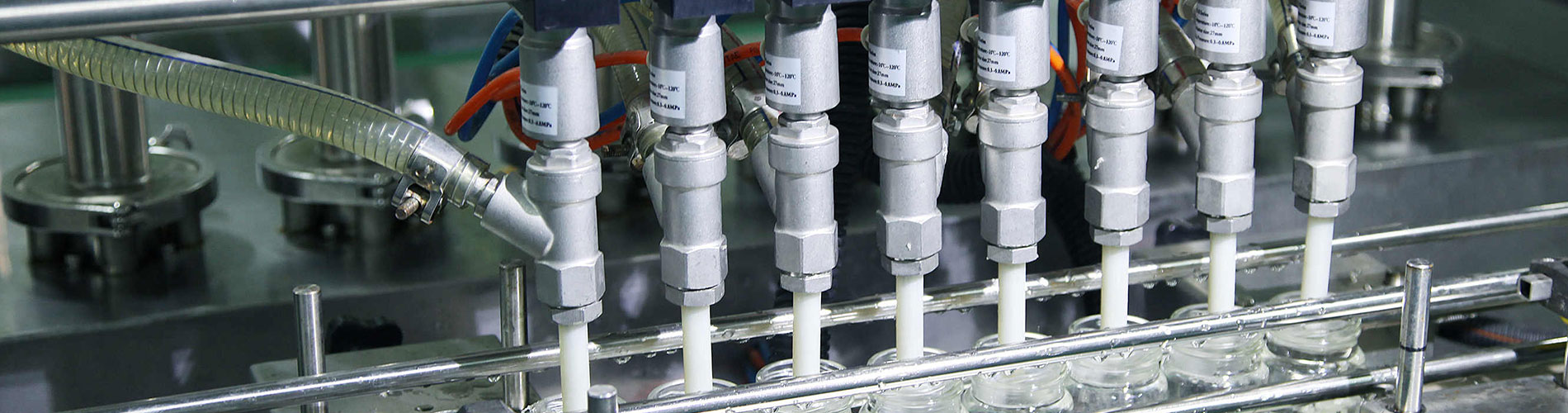

Magbasa paMagpadala ng InquiryFood Process Machine Steel Lost Wax Casting Parts

Ang Maple machinery ay isang internasyonal na tagagawa ng metal na gumagawa ng mga haluang metal at proseso para sa mataas na pagganap ng mga bahagi ng cast para sa makinarya ng pagkain, langis at gas, windmill at haydrolika, bakal at higit pa sa loob ng maraming taon. Ang makinarya ng Maple ay nakakuha ng isang pandaigdigang reputasyon sa industriya para sa pagtugon sa mga kinakailangan ng customer sa pamamagitan ng kilalang solidong teknikal na kadalubhasaan nito. Ang diskarte ng Maple machinery ay upang bigyan ang mga customer nito ng mataas na kalidad na Food Process Machine Steel Lost Wax Casting Parts sa pamamagitan ng isang kultura ng pagganap batay sa pagbabago, pagiging maaasahan at proteksyon sa kapaligiran.

Magbasa paMagpadala ng InquiryValve Steel Lost Wax Casting Parts

Ang sopistikadong teknikal na kadalubhasaan at karanasan ng Maple machinery ay nagbibigay-inspirasyon at nag-uudyok sa amin na pumasok sa larangan ng precision Precision Castings na ginagawa namin ang Valve Steel Lost Wax Casting Parts hanggang sa perpekto. Kami ay isang pangkat ng mga kwalipikado at may karanasang metalurhiko at mekanikal na mga inhinyero. Ang aming pabrika ay matatagpuan sa Ningbo, China. Upang gawing perpekto ang aming mga produkto, na-install namin ang pinaka-advanced na kagamitan at makina. Nag-set up din kami ng sarili naming laboratoryo, na nilagyan ng pinakabagong mga instrumento upang matiyak ang ultra-smooth finish, dimensional accuracy at kinakailangang tigas, at upang matukoy ang tumpak na mga porsyento ng metal.

Magbasa paMagpadala ng InquiryMalakas na Industriya Steel Lost Wax Casting Parts

Sa pamamagitan ng isang matatag na sistema ng pamamahala ng kalidad, walang kompromiso na pagsunod sa itinatag na mga pamantayan, walang humpay na pagtutok sa katumpakan, at patuloy na paghahangad ng pagpapabuti at kasiyahan ng customer - lahat ito ay mga elementong tumutulong sa amin na maihatid ang pinakamataas na kalidad ng Heavy Industry Steel Lost Wax Casting Parts sa aming mga customer sa buong mundo.

Magbasa paMagpadala ng InquiryOff Highway Industry Steel Lost Wax Casting Parts

Maple machinery has a number of casting plants, with strong processing capacity Specializing in the production of carbon steel, alloy steel, stainless steel, high temperature alloy and other wax lost casting parts and machining parts. Maple's superior quality of Off Highway Industry Steel Lost Wax Casting Parts attracts equally excellent customers, enabling our products to serve various machinery industries. 产品内容 Off Highway Industry Steel Lost Wax Casting Parts Product Introduction Off Highway Industry Steel Lost Wax Casting Parts is a product that Maple machinery has been doing. Lost wax casting is now called investment casting. It is a precision casting process with little or no cutting. It is not only suitable for precision casting of various types and alloys, but also produces castings with higher dimensional accuracy and surface quality than other precision casting methods. In order to meet the needs of different customers, we use two kinds of wax, namely yellow low temperature wax and green medium temperature wax. 2. Product Parameter (Specification) Item Off Highway Industry Steel Lost Wax Casting Parts Roughness Ra 1.6 Tolerance ±0.01mm Material Casting Steel/Casting Iron Certification ISO 9001:2015 Weight 0.01-5000KG Machining CNC Heat Treatment Quenching & Tempering Inspection MT/UT/X-Ray Lead Time 30 Days Package Plywood Case Method Sand Casting Capacity 50000 Pcs / Month Origin Ningbo, China 3. Maple’s Services for Off Highway Industry Maple machinery has been increasing its manufacturing capacity for Off Highway Industry Steel Lost Wax Casting Parts for many years. Provide high quality Off Highway Industry Steel Lost Wax Casting Parts for our machining operations to meet and satisfy customer needs. We are able to process different types of castings, including: pressure die casting and sand castings. We assist our customers to select the most appropriate casting type according to the required volume and complexity, providing the most cost effective solution. The railway sector provides a crucial network for transport and distribution. It needs cost-effective and long-lasting equipment that is dependable for the range of applications. The railways, from freight to passenger, need different castings for various applications. Maple Machinery carries extensive experience to create steel castings and iron castings in varying sizes, shapes, and materials that are precise, strong, and durable. We manufacture a wide range of castings and forgings for railway infrastructure and transportation equipment. 4.Supporting Service for Off Highway Industry parts As mentioned above, in order to work in adverse conditions, the performance of the Off Highway Industry Steel Lost Wax Casting Parts must be excellent. Therefore, it’s not enough to only produce raw castings or forgings, but also need heat treatment, machining, surface treatment, NDT testing, etc. Heat treatment: heat treatment is the critical step to improve the mechanical properties of the workpiece. We can formulate the process according to the strength requirements of the parts, and improve the mechanical properties of the parts such as hardness, yield strength, tensile strength and elongation by heat treatment Machining: we have our own machine shop, and can complete almost all machining requirements with advanced equipment. Surface treatment: the purpose of surface treatment is to make parts work in adverse environment. Zinc plating can prevent parts from rusting; Nickel plating can enhance the wear resistance and corrosion resistance of parts; Phosphating can prevent parts from corrosion… Non-destructive testing (NDT): NDT is the last and most important step. Maple will NDT the parts to ensure that there are no surface defects (such as cracks, sand holes, blow holes) and no internal defects (shrinkage and slag) on the delivered parts. Common Material for Off Highway Industry parts We have the ability to manufacture all steel standard materials as well as special materials. The following are our common materials for manufacturing Off Highway Industry Steel Lost Wax Casting Parts: Carbon Steel:1015, 1020, 1035, 1045, 20Mn, 25Mn, A570.GrA, SJ355, C45… Alloy Steel:4130, 4135, 4140, 4340, 8620, 8640, 20CrMo, 42CrMo4, 34CrNiMo6, 25CrMo… Stainless steel:304, 304L, 316, 316L, 410, 416, CF8, CF8M, PH17-4, CK20… Gray Iron:GG-15, GG-20, GG-25, Class 20B, Class 25B, Class 30B, GJL-250, GJL-300… Ductile Iron:GGG-40, GGG-50, 60-40-18, 65-45-12, 70-50-05, 80-55-06 QT500-7, QT400-18, QT700-2 … High Chromium cast iron:15%Cr-Mo-HC, 20%Cr-Mo-LC, 25%Cr… Aluminum:AlSi7Mg, AlSi12, AlSi10Mg, A356, A360… High Manganese steel: X120Mn12, Mn12, Mn13… 5.The Parts We Supplying for the Off Highway Industry We have manufactured a wide range of Off Highway Industry Steel Lost Wax Casting Parts. The following are typical products: Coupling components, Centre plates, Bearing brackets, Rail wheels, Wheel hub, Base plate, Axle boxes, Yokes, Pedestals, Hinges, Tie plates, Side jaw clip, and Joint bar. 6. Why Sand Casting Sand casting is an ancient casting process where the metal parts are molded by pouring metal into a hollow cavity. The mold-based manufacturing process is used to make castings with materials of iron, steel, and Aluminum. Casting-based manufacturing includes several steps and can create a wide range of shapes and sizes for metal products. The process begins with the making of a mold pattern and a gate system with the exact size and shape of the required part. The temperature required depends on the metal as some metals take a long time to heat and melt. Maple Machinery has continuously upgraded its Sand-casting equipment and refined the casting process. The aim behind this is to use only the advanced casting technology for its Sand-casting operations. Each step follows the customer’s drawings and instructions to deliver precise solutions.

Magbasa paMagpadala ng InquiryOil at Gas Industry Steel Lost Wax Casting Parts

Ang Maple ay isang foundry at processing company na may malawak na karanasan, at malaki ang aming kumpiyansa na gawin ang aming makakaya sa Oil & Gas Industry Steel Lost Wax Casting Parts. Ang aming Lost Wax Casting expert ay nariyan para tulungan ka sa lahat ng pinakamahusay na solusyon. Matugunan ang iyong pangangailangan para sa produktong kailangan mo

Magbasa paMagpadala ng Inquiry