Tawagan Kami

+86-19858305627

Mag-email sa Amin

sales@maple-machinery.com

Banayad na Steel Casting Component para sa Oil & Gas Industry Mga Manufacturer

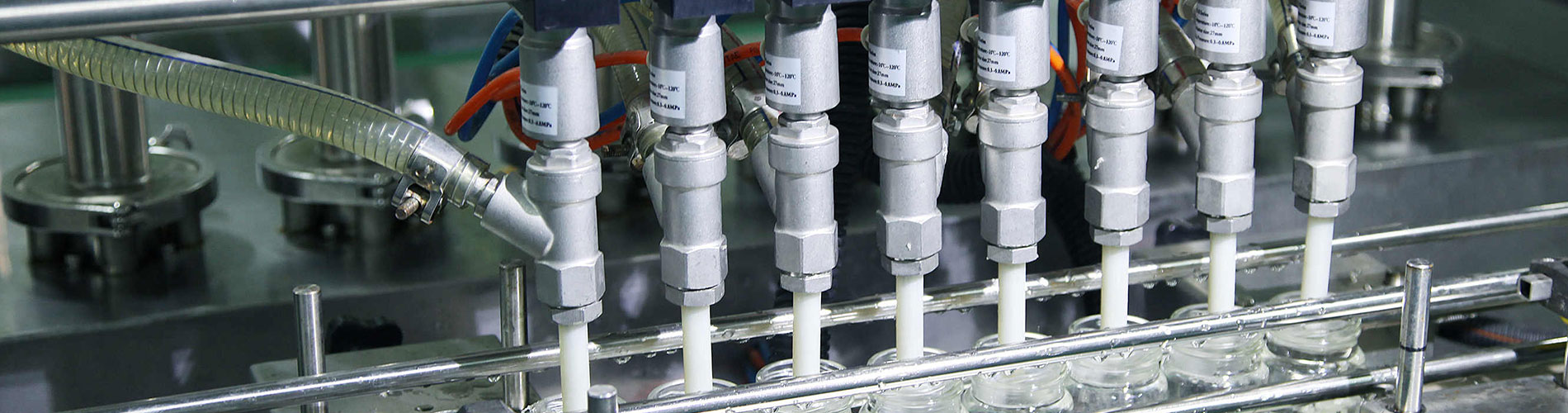

Nagbibigay ang aming pabrika ng sand casting, closed die forging, open die forging, atbp. Ang matinding disenyo, kalidad ng mga hilaw na materyales, mataas na pagganap at mapagkumpitensyang presyo ang gusto ng bawat customer, at iyon din ang maiaalok namin sa iyo. Kumuha kami ng mataas na kalidad, makatwirang presyo at perpektong serbisyo.

Mainit na Produkto

Balbula iron sand cast bahagi

Ang Maple, na matatagpuan sa China, ay nangunguna sa kahusayan sa pagmamanupaktura, na dalubhasa sa Valve Iron Sand Cast Parts. Sa pagtutok sa tatlong mahahalagang keyword na ito, ang aming pangako sa katumpakan at kalidad ay hindi natitinag. Pinagsasama namin ang mga advanced na diskarte at makabagong teknolohiya sa aming mga proseso ng iron sand casting, tinitiyak na ang bawat bahagi ng balbula ay nakakatugon sa pinakamataas na pamantayan. Bilang isang pinagkakatiwalaang pangalan sa industriya, ang kadalubhasaan ng Maple ay nakasalalay sa paghahatid ng mga iniangkop na solusyon para sa magkakaibang hanay ng mga aplikasyon, na nagpapatatag sa aming posisyon bilang isang maaasahang provider ng mga bahagi ng valve iron sand cast sa merkado ng China at higit pa.Hydraulic System Steel Forging Parts

Maple machinery ay isang kumpleto at ganap na pinagsama-samang forging at processing equipment, na dalubhasa sa mga customized na proyekto sa pagmamanupaktura. Carbon, haluang metal at hindi kinakalawang na asero Hydraulic System Steel Forging Parts, timbang 0.1kg-60kg. Maaaring bawasan ng maple ang pagkaantala ng heat treatment, forging at delivery, at pagbutihin ang kalidad.Heavy Industry Steel Precision Casting Parts

Ang makinarya ng maple ay may pinakamaaasahang produkto at serbisyo. Nagagawa rin namin na makamit ang pinaka-pare-parehong supply at ang pinakamahusay na kalidad ng kaligtasan dahil sa aming mahusay na vertical integration - ang kakayahang magbigay ng ganap na solusyon sa serbisyo mula sa pagmimina hanggang sa produksyon. Samakatuwid, ang Heavy Industry Steel Precision Casting Parts para sa makinarya ng Maple ay ganap na gawin itong pinakamahusay na magagawa nito.Hydraulic System Steel Precision Casting Parts

Maple machinery ay may isang malakas na teknolohiya sa pagbuo at makabagong kakayahan upang matugunan ang mga kinakailangan sa produksyon ng Hydraulic System Steel Precision Casting Parts. Aktibo kaming nakipagtulungan sa mga namumukod-tanging pang-internasyonal na negosyo upang bumuo ng isang batch ng Hydraulic System Steel Precision Casting Parts na may mga competitive na bentahe. Ang kumpanya ay may malakas na teknikal na puwersa, kumpletong propesyonal na kagamitan, mahigpit na kontrol sa kalidad. Alam na alam ng aming kumpanya na ang kumpetisyon ng produkto ay nakabatay sa pagbuo ng mga bagong produkto, pagkamalikhain ng tao at kontrol sa kalidad, kaya kami ay bumubuo ng mga mapagkumpitensyang produkto sa pamamagitan ng sistematikong diskarte sa pamamahala at akumulasyon ng teknolohiya.Mga Bahagi ng Valve Stainless Steel Forging

Pagproseso ng Valve Stainless Steel Forging Parts Mayroon kaming lahat ng mga kumbensyonal na pamamaraan para sa pag-forging ng mga bahagi. Kasama sa saklaw ng aming mga serbisyo ang pagpoproseso ng mga stainless steel die forging, lalo na ang mga operasyon sa paggiling at pag-turn sa CNC machine tools. Ayon sa mga kinakailangan ng mga customer, maaari rin kaming magbigay ng pakikipagtulungan sa iba pang mga pabrika.Makinarya sa Konstruksyon Mga Bahagi ng Hindi kinakalawang na Steel Casting

Ang Maple machinery ay isang tagagawa ng cast stainless steel parts na nakabase sa Ningbo, China. Mayroon kaming mahabang kasaysayan ng pagbibigay ng Construction Machinery ng Stainless Steel Casting Parts. Bilang karagdagan, nag-aalok kami ng one-stop casting solution na sumasaklaw sa lahat ng proseso ng pagmamanupaktura. Ang aming pangunahing driver ay ang patuloy na pagpapabuti at pamumuhunan sa pagbabago at kalidad sa pamamagitan ng mga napapanatiling solusyon. Regular naming ina-audit ang aming mga produkto at proseso ayon sa pinakamahigpit na pamantayan sa pamamagitan ng mga neutral na ahensya. Samakatuwid, kapag ginamit mo ang aming Construction Machinery Stainless Steel Casting Parts, maaari kang maging kumpiyansa na nakakatugon ito sa 100% ng mga naaangkop na nauugnay na pamantayan.

Magpadala ng Inquiry

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy